Optimize, Monitor and Control your Factory with Software

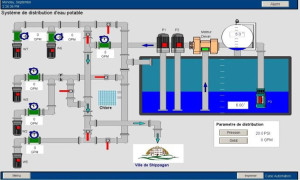

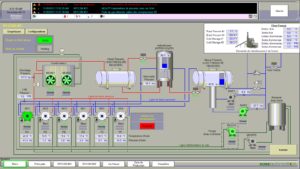

Process Monitoring

As processes become more complex and efficiency more important, process visualization and optimization becomes more critical.

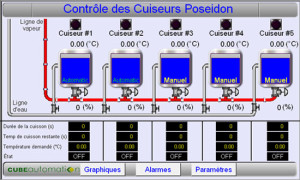

Using technologies such as SCADA, HMI, Historians and Big Data Servers, Cube Automation monitor complete factories or individual processes:

- Water and Waste Water Systems

- Boiler/Cooker Systems

- Refrigeration/Freezer Systems

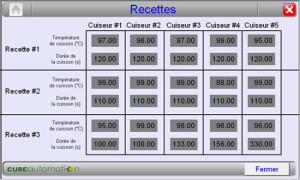

- Recipe and Mixing Systems

- Paperless Quality Assurance

- Machine and Factory Performance

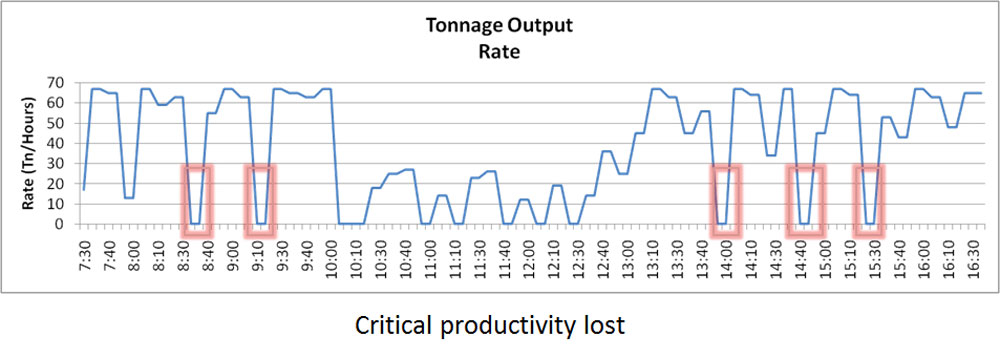

Peak Performance Machine Monitoring

As machines are getting more complex, the ability to monitor the performance and the key productivity indicators (KPI) become more valuable. Cube’s team has the ability to integrate industrial software and help improve machine efficiency. Visualize and Optimize your machine operation with the Smart Factoree™ Productivity Analysis module for monitoring downtime, OEE and equipment activity.

Scale & Weight Monitoring

Monitor your package weight precision and the productivity of the operators. By tracking the weight of each individual package, who pack it and at which rate, factories find quick payback with our technologies. Cube Automation can connect your scales (fix or dynamic) and help you visualize your process performance. We can also integrate full Piecework tracking and complex Traceability Systems.

Factory wide Label & Printer Control

From a simple stand-alone printer to integrated production line automated labelling systems, Cube Automation offers the hardware and expertise to integrate them all. We also offer advanced inventory and traceability solutions.